CANDHy begins: hydrogen-proof cast iron

Four European laboratories are investigating whether natural gas pipelines can transport the fuel of the future.

Some questions sound simple but conceal a fascinating complexity: Can current natural gas distribution networks transport hydrogen? That is basically the question CANDHy is answering. And the answer is not in the books, but in the laboratories.

Round robin test: when four brains think better than one

CANDHy’s first testing campaign is now underway, and the initial results are starting to come in. But this is not a laboratory working alone. It is a Round Robin Test, a methodology where four independent R&D platforms work in parallel to validate and compare results.

The protagonists? Aragon Hydrogen Foundation (us), NATRAN, TECNALIA and RINA. Four centres, one common goal: to understand what happens when hydrogen encounters materials that have been transporting natural gas for decades.

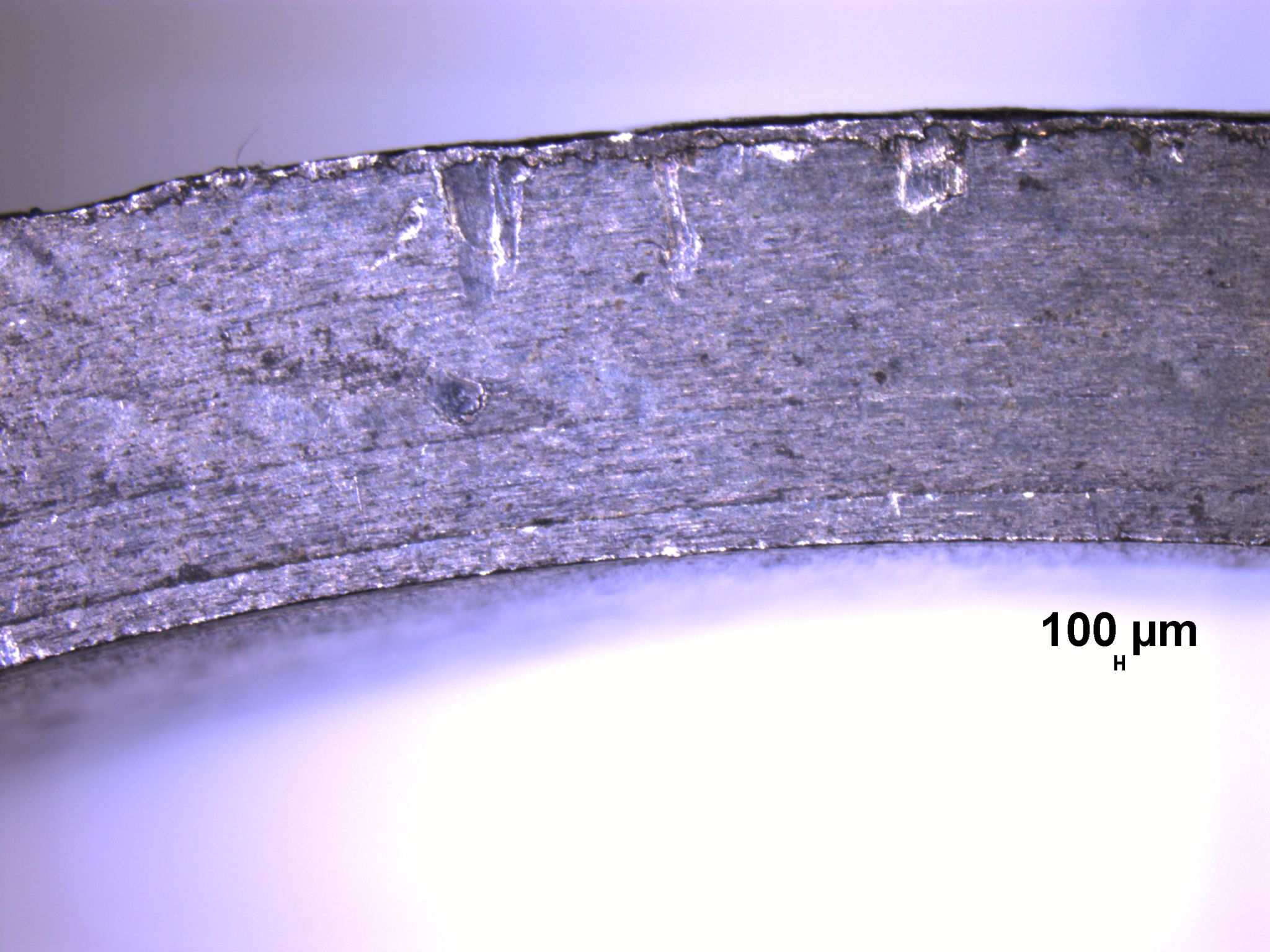

Cast iron under the microscope

The tests are no small matter. We are subjecting grey and ductile cast iron materials — both new and vintage, extracted from the actual natural gas network — to dynamic and static load tests in the presence of hydrogen.

Why cast iron? Because it is the predominant material in thousands of kilometres of gas distribution pipes in Europe. If we want these same networks to transport hydrogen in the future, we need to know for sure whether these materials are compatible or whether hydrogen will embrittle them (technically known as “hydrogen embrittlement”).

And no, assumptions are not enough. We need hard science, rigorous testing and verified data.

Beyond trials: models, guidelines, and databases

The results we are obtaining will not remain in technical reports stored away in a drawer. They will be used to:

Develop predictive models that anticipate hydrogen embrittlement mechanisms.

Propose technical guidelines to support future regulations on testing and qualifying materials for distribution networks.

Create a technical database on metal compatibility with hydrogen.

In other words, we are building the technical knowledge that will enable informed decisions to be made about the future of gas infrastructure in Europe.

The project is progressing as planned, and the partners are working hard to maximise results. Accurately predicting the behaviour of these materials in hydrogen conditions is not just a technical exercise: it is a key factor in safely accelerating the energy transition.

At Fundación Hidrógeno Aragón, we continue to contribute our expertise in testing and characterising materials. Because the future of hydrogen is not built solely on electrolysers and fuel cells, it is also built on understanding what happens inside a pipe when hydrogen flows through it.

And that, believe us, is as fascinating as it is complex.

🔗 More information about CANDHy 📧 Contact FHa: info@hidrogenoaragon.org